Page 8 - metal2022

P. 8

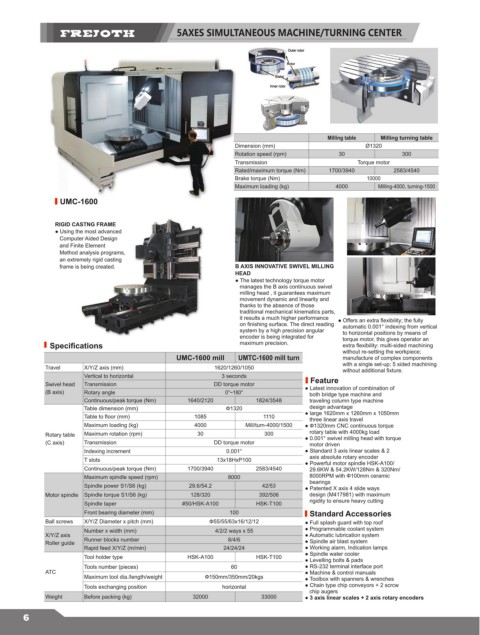

5AXES SIMULTANEOUS MACHINE/TURNING CENTER

Milling table Milling turning table

Dimension (mm) Ø1320

Rotation speed (rpm) 30 300

Transmission Torque motor

Rated/maximum torque (Nm) 1700/3940 2583/4540

Brake torque (Nm) 10000

Maximum loading (kg) 4000 Milling-4000, turning-1500

UMC-1600

RIGID CASTNG FRAME

● Using the most advanced

Computer Aided Design

and Finite Element

Method analysis programs,

an extremely rigid casting

frame is being created. B AXIS INNOVATIVE SWIVEL MILLING

HEAD

● The latest technology torque motor

manages the B axis continuous swivel

milling head , it guarantees maximum

movement dynamic and linearity and

thanks to the absence of those

traditional mechanical kinematics parts,

it results a much higher performance ● Offers an extra flexibility; the fully

on finishing surface. The direct reading automatic 0.001° indexing from vertical

system by a high precision angular to horizontal positions by means of

encoder is being integrated for torque motor, this gives operator an

Specifications maximum precision. extra flexibility: multi-sided machining

without re-setting the workpiece;

UMC-1600 mill UMTC-1600 mill turn manufacture of complex components

Travel X/Y/Z axis (mm) 1620/1260/1050 with a single set-up; 5 sided machining

without additional fixture.

Vertical to horizontal 3 seconds Feature

Swivel head Transmission DD torque motor ● Latest innovation of combination of

(B axis) Rotary angle 0°~180° both bridge type machine and

Continuous/peak torque (Nm) 1640/2120 1824/3548 traveling column type machine

Table dimension (mm) Ф1320 design advantage

Table to floor (mm) 1085 1110 ● large 1620mm x 1260mm x 1050mm

three linear axis travel

Maximum loading (kg) 4000 Mill/turn-4000/1500 ● Ф1320mm CNC continuous torque

Rotary table Maximum rotation (rpm) 30 300 rotary table with 4000kg load

● 0.001° swivel milling head with torque

(C axis) Transmission DD torque motor motor driven

Indexing increment 0.001° ● Standard 3 axis linear scales & 2

T slots 13x18HxP100 axis absolute rotary encoder

● Powerful motor spindle HSK-A100/

Continuous/peak torque (Nm) 1700/3940 2583/4540 29.6KW & 54.2KW/128Nm & 320Nm/

Maximum spindle speed (rpm) 8000 8000RPM with Ф100mm ceramic

Spindle power S1/S6 (kg) 29.6/54.2 42/53 bearings

● Patented X axis 4 slide ways

Motor spindle Spindle torque S1/S6 (kg) 128/320 392/506 design (M417981) with maximum

Spindle taper #50/HSK-A100 HSK-T100 rigidity to ensure heavy cutting

Front bearing diameter (mm) 100 Standard Accessories

Ball screws X/Y/Z Diameter x pitch (mm) Ф55/55/63x16/12/12 ● Full splash guard with top roof

Number x width (mm) 4/2/2 ways x 55 ● Programmable coolant system

X/Y/Z axis Runner blocks number 8/4/6 ● Automatic lubrication system

Roller guide ● Spindle air blast system

Rapid feed X/Y/Z (m/min) 24/24/24 ● Working alarm, Indication lamps

● Spindle water cooler

Tool holder type HSK-A100 HSK-T100

● Levelling bolts & pads

Tools number (pieces) 60 ● RS-232 terminal interface port

ATC ● Machine & control manuals

Maximum tool dia./length/weight Ф150mm/350mm/20kgs ● Toolbox with spanners & wrenches

Tools exchanging position horizontal ● Chain type chip conveyors + 2 scrcw

chip augers

Weight Before packing (kg) 32000 33000 ● 3 axis linear scales + 2 axis rotary encoders

6