Page 22 - metal2022

P. 22

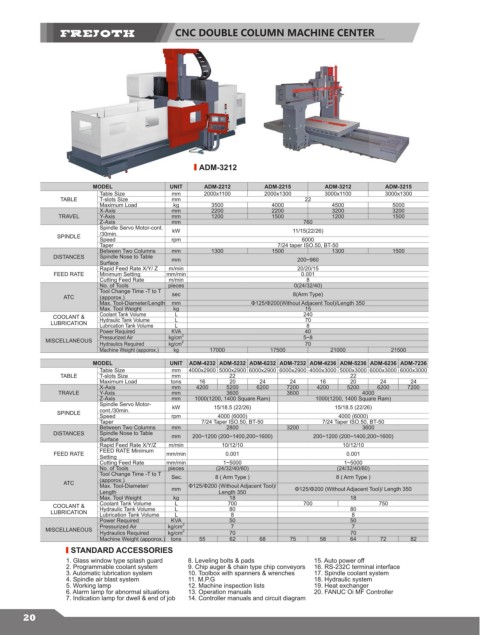

CNC DOUBLE COLUMN MACHINE CENTER

ADM-3212

MODEL UNIT ADM-2212 ADM-2215 ADM-3212 ADM-3215

Table Size mm 2000x1100 2000x1300 3000x1100 3000x1300

TABLE T-slots Size mm 22

Maximum Load kg 3500 4000 4500 5000

X-Axis mm 2200 2200 3200 3200

TRAVEL Y-Axis mm 1200 1500 1200 1500

Z-Axis mm 760

Spindle Servo Motor-cont. kW 11/15(22/26)

SPINDLE /30min.

Speed rpm 6000

Taper 7/24 taper ISO.50, BT-50

Between Two Columns mm 1300 1500 1300 1500

DISTANCES Spindle Nose to Table mm 200~960

Surface

Rapid Feed Rate X/Y/ Z m/min 20/20/15

FEED RATE Minimum Setting mm/min 0.001

Cutting Feed Rate m/min 8

No. of Tools pieces 0(24/32/40)

Tool Change Time -T to T

ATC (apporox.) sec 8(Arm Type)

Max. Tool-Diameter/Length mm Φ125/Φ200(Without Adjacent Tool)/Length 350

Max. Tool Weight kg 15

COOLANT & Coolant Tank Volume L 240

LUBRICATION Hydraulic Tank Volume L L 70

Lubrication Tank Volume

8

Power Required KVA 40

Pressurized Air kg/cm 2 5~8

MISCELLANEOUS 2

Hydraulics Required kg/cm 70

Machine Weight (apporox.) kg 17000 17500 21000 21500

MODEL UNIT ADM-4232 ADM-5232 ADM-6232 ADM-7232 ADM-4236 ADM-5236 ADM-6236 ADM-7236

Table Size mm 4000x2900 5000x2900 6000x2900 6000x2900 4000x3000 5000x3000 6000x3000 6000x3000

TABLE T-slots Size mm 22 22

Maximum Load tons 16 20 24 24 16 20 24 24

X-Axis mm 4200 5200 6200 7200 4200 5200 6200 7200

TRAVLE Y-Axis mm 3600 3600 4000

Z-Axis mm 1000(1200, 1400 Square Ram) 1000(1200, 1400 Square Ram)

Spindle Servo Motor- kW 15/18.5 (22/26) 15/18.5 (22/26)

SPINDLE cont./30min.

Speed rpm 4000 (6000) 4000 (6000)

Taper 7/24 Taper ISO.50, BT-50 7/24 Taper ISO.50, BT-50

Between Two Columns mm 2800 3200 3600

DISTANCES Spindle Nose to Table mm 200~1200 (200~1400,200~1600) 200~1200 (200~1400,200~1600)

Surface

Rapid Feed Rate X/Y/Z m/min 10/12/10 10/12/10

FEED RATE FEED RATE Minimum mm/min 0.001 0.001

Setting

Cutting Feed Rate mm/min 1~5000 1~5000

No. of Tools pieces (24/32/40/60) (24/32/40/60)

Tool Change Time -T to T Sec. 8 ( Arm Type ) 8 ( Arm Type )

ATC (apporox.)

Max. Tool-Diameter/ mm Φ125/Φ200 (Without Adjacent Tool)/ Φ125/Φ200 (Without Adjacent Tool)/ Length 350

Length Length 350

Max. Tool Weight kg 18 18

COOLANT & Coolant Tank Volume L 700 700 750

LUBRICATION Hydraulic Tank Volume L L 80 80

Lubrication Tank Volume

8

8

Power Required KVA 50 50

Pressurized Air kg/cm 2 7 7

MISCELLANEOUS 2

Hydraulics Required kg/cm 70 70

Machine Weight (apporox.) tons 55 62 68 75 58 64 72 82

STANDARD ACCESSORIES

1. Glass window type splash guard 8. Leveling bolts & pads 15. Auto power off

2. Programmable coolant system 9. Chip auger & chain type chip conveyors 16. RS-232C terminal interface

3. Automatic lubrication system 10. Toolbox with spanners & wrenches 17. Spindle coolant system

4. Spindle air blast system 11. M.P.G 18. Hydraulic system

5. Working lamp 12. Machine inspection lists 19. Heat exchanger

6. Alarm lamp for abnormal situations 13. Operation manuals 20. FANUC Oi MF Controller

7. Indication lamp for dwell & end of job 14. Controller manuals and circuit diagram

20