Page 36 - metal2022

P. 36

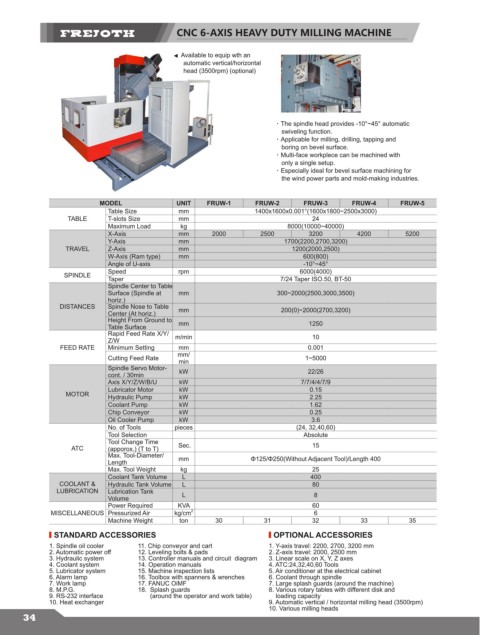

CNC 6-AXIS HEAVY DUTY MILLING MACHINE

▲ Available to equip wth an

automatic vertical/horizontal

head (3500rpm) (optional)

‧The spindle head provides -10°~45° automatic

swiveling function.

‧Applicable for milling, drilling, tapping and

boring on bevel surface.

‧Multi-face workplece can be machined with

only a single setup.

‧Especially ideal for bevel surface machining for

the wind power parts and mold-making industries.

MODEL UNIT FRUW-1 FRUW-2 FRUW-3 FRUW-4 FRUW-5

Table Size mm 1400x1600x0.001°(1600x1800~2500x3000)

TABLE T-slots Size mm 24

Maximum Load kg 8000(10000~40000)

X-Axis mm 2000 2500 3200 4200 5200

Y-Axis mm 1700(2200,2700,3200)

TRAVEL Z-Axis mm 1200(2000,2500)

W-Axis (Ram type) mm 600(800)

Angle of U-axis -10°~45°

Speed rpm 6000(4000)

SPINDLE

Taper 7/24 Taper ISO.50, BT-50

Spindle Center to Table

Surface (Spindle at mm 300~2000(2500,3000,3500)

horiz.)

DISTANCES Spindle Nose to Table mm 200(0)~2000(2700,3200)

Center (At horiz.)

Height From Ground to mm 1250

Table Surface

Rapid Feed Rate X/Y/

Z/W m/min 10

FEED RATE Minimum Setting mm 0.001

mm/

Cutting Feed Rate min 1~5000

Spindle Servo Motor-

cont. / 30min kW 22/26

Axis X/Y/Z/W/B/U kW 7/7/4/4/7/9

Lubricator Motor kW 0.15

MOTOR Hydraulic Pump kW 2.25

Coolant Pump kW 1.62

Chip Conveyor kW 0.25

Oil Cooler Pump kW 3.6

No. of Tools pieces (24, 32,40,60)

Tool Selection Absolute

Tool Change Time

ATC (apporox.) (T to T) Sec. 15

Max. Tool-Diameter/ mm Φ125/Φ250(Without Adjacent Tool)/Length 400

Length

Max. Tool Weight kg 25

Coolant Tank Volume L 400

COOLANT & Hydraulic Tank Volume L 80

LUBRICATION Lubrication Tank

Volume L 8

Power Required KVA 60

MISCELLANEOUS Pressurized Air kg/cm 2 6

Machine Weight ton 30 31 32 33 35

STANDARD ACCESSORIES OPTIONAL ACCESSORIES

1. Spindle oil cooler 11. Chip conveyor and cart 1. Y-axis travel: 2200, 2700, 3200 mm

2. Automatic power off 12. Leveling bolts & pads 2. Z-axis travel: 2000, 2500 mm

3. Hydraulic system 13. Controller manuals and circuit diagram 3. Linear scale on X, Y, Z axes

4. Coolant system 14. Operation manuals 4. ATC:24,32,40,60 Tools

5. Lubricator system 15. Machine inspection lists 5. Air conditioner at the electrical cabinet

6. Alarm lamp 16. Toolbox with spanners & wrenches 6. Coolant through spindle

7. Work lamp 17. FANUC OiMF 7. Large splash guards (around the machine)

8. M.P.G. 18. Splash guards 8. Various rotary tables with different disk and

9. RS-232 interface (around the operator and work table) loading capacity

10. Heat exchanger 9. Automatic vertical / horizontal milling head (3500rpm)

10. Various milling heads

34