Page 41 - metal2022

P. 41

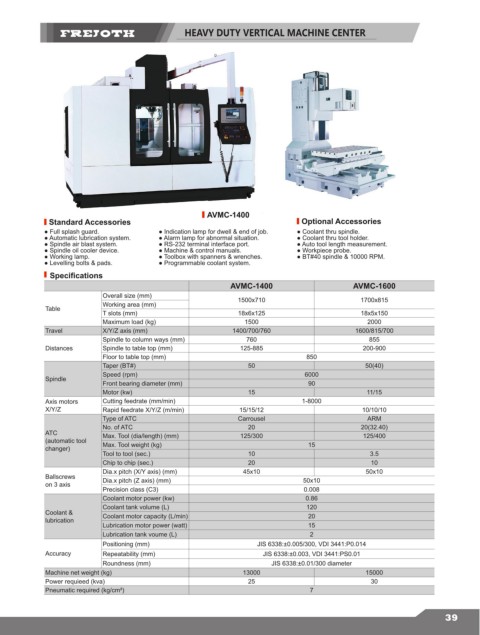

HEAVY DUTY VERTICAL MACHINE CENTER

AVMC-1400

Standard Accessories Optional Accessories

● Full splash guard. ● Indication lamp for dwell & end of job. ● Coolant thru spindle.

● Automatic lubrication system. ● Alarm lamp for abnormal situation. ● Coolant thru tool holder.

● Spindle air blast system. ● RS-232 terminal interface port. ● Auto tool length measurement.

● Spindle oil cooler device. ● Machine & control manuals. ● Workpiece probe.

● Working lamp. ● Toolbox with spanners & wrenches. ● BT#40 spindle & 10000 RPM.

● Levelling bolts & pads. ● Programmable coolant system.

Specifications

AVMC-1400 AVMC-1600

Overall size (mm) 1500x710 1700x815

Working area (mm)

Table

T slots (mm) 18x6x125 18x5x150

Maximum load (kg) 1500 2000

Travel X/Y/Z axis (mm) 1400/700/760 1600/815/700

Spindle to column ways (mm) 760 855

Distances Spindle to table top (mm) 125-885 200-900

Floor to table top (mm) 850

Taper (BT#) 50 50(40)

Speed (rpm) 6000

Spindle

Front bearing diameter (mm) 90

Motor (kw) 15 11/15

Axis motors Cutting feedrate (mm/min) 1-8000

X/Y/Z Rapid feedrate X/Y/Z (m/min) 15/15/12 10/10/10

Type of ATC Carrousel ARM

No. of ATC 20 20(32.40)

ATC Max. Tool (dia/length) (mm) 125/300 125/400

(automatic tool Max. Tool weight (kg) 15

changer)

Tool to tool (sec.) 10 3.5

Chip to chip (sec.) 20 10

Dia.x pitch (X/Y axis) (mm) 45x10 50x10

Ballscrews Dia.x pitch (Z axis) (mm) 50x10

on 3 axis

Precision class (C3) 0.008

Coolant motor power (kw) 0.86

Coolant tank volume (L) 120

Coolant & Coolant motor capacity (L/min) 20

lubrication

Lubrication motor power (watt) 15

Lubrication tank voume (L) 2

Positioning (mm) JIS 6338:±0.005/300, VDI 3441:P0.014

Accuracy Repeatability (mm) JIS 6338:±0.003, VDI 3441:PS0.01

Roundness (mm) JIS 6338:±0.01/300 diameter

Machine net weight (kg) 13000 15000

Power requieed (kva) 25 30

Pneumatic required (kg/cm²) 7

39