Page 71 - metal2022

P. 71

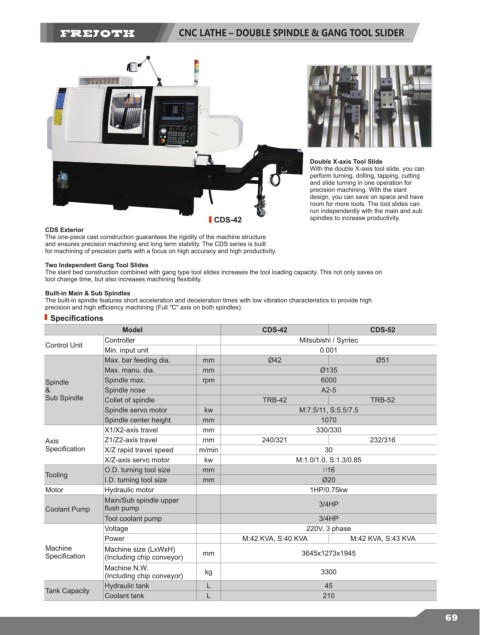

CNC LATHE – DOUBLE SPINDLE & GANG TOOL SLIDER

Double X-axis Tool Slide

With the double X-axis tool slide, you can

perform turning, drilling, tapping, cutting

and slide turning in one operation for

precision machining. With the slant

design, you can save on space and have

room for more tools. The tool slides can

run independently with the main and sub

CDS-42 spindles to increase productivity.

CDS Exterior

The one-piece cast construction guarantees the rigidity of the machine structure

and ensures precision machining and long term stability. The CDS series is built

for machining of precision parts with a focus on high accuracy and high productivity.

Two Independent Gang Tool Slides

The slant bed construction combined with gang type tooI slides increases the tool loading capacity. This not only saves on

tool change time, but also increases machining flexibility.

Built-in Main & Sub Spindles

The built-in spindle features short acceleration and deceleration times with low vibration characteristics to provide high

precision and high efficiency machining (Full "C" axis on both spindles).

Specifications

Model CDS-42 CDS-52

Controller Mitsubishi / Syntec

Control Unit

Min. input unit 0.001

Max. bar feeding dia. mm Ø42 Ø51

Max. manu. dia. mm Ø135

Spindle Spindle max. rpm 6000

& Spindle nose A2-5

Sub Spindle Collet of spindle TRB-42 TRB-52

Spindle servo motor kw M:7.5/11, S:5.5/7.5

Spindle center height mm 1070

X1/X2-axis travel mm 330/330

Axis Z1/Z2-axis travel mm 240/321 232/316

Specification X/Z rapid travel speed m/min 30

X/Z-axis servo motor kw M:1.0/1.0, S:1.3/0.85

O.D. turning tool size mm □16

Tooling

I.D. turning tool size mm Ø20

Motor Hydraulic motor 1HP/0.75kw

Main/Sub spindle upper 3/4HP

Coolant Pump flush pump

Tool coolant pump 3/4HP

Voltage 220V, 3 phase

Power M:42 KVA, S:40 KVA M:42 KVA, S:43 KVA

Machine Machine size (LxWxH)

Specification (Including chip conveyor) mm 3645x1273x1945

Machine N.W. kg 3300

(Including chip conveyor)

Hydraulic tank L 45

Tank Capacity

Coolant tank L 210

69