Page 138 - metal2022

P. 138

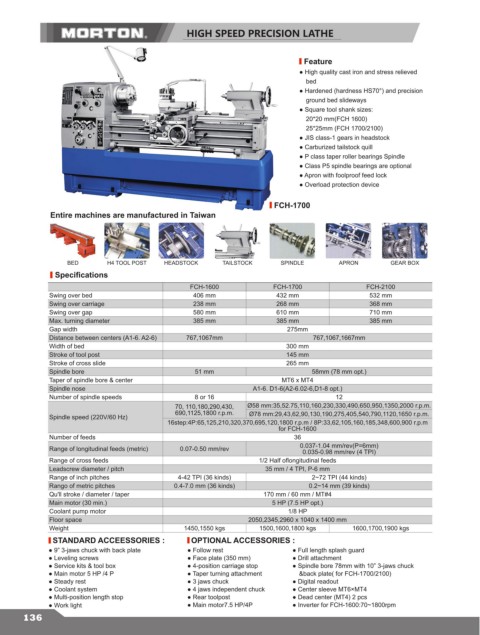

HIGH SPEED PRECISION LATHE

Feature

● High quality cast iron and stress relieved

bed

● Hardened (hardness HS70°) and precision

ground bed slideways

● Square tool shank sizes:

20*20 mm(FCH 1600)

25*25mm (FCH 1700/2100)

● JIS class-1 gears in headstock

● Carburized tailstock quill

● P class taper roller bearings Spindle

● Class P5 spindle bearings are optional

● Apron with foolproof feed lock

● Overload protection device

FCH-1700

Entire machines are manufactured in Taiwan

BED H4 TOOL POST HEADSTOCK TAILSTOCK SPINDLE APRON GEAR BOX

Specifications

FCH-1600 FCH-1700 FCH-2100

Swing over bed 406 mm 432 mm 532 mm

Swing over carriage 238 mm 268 mm 368 mm

Swing over gap 580 mm 610 mm 710 mm

Max. turning diameter 385 mm 385 mm 385 mm

Gap width 275mm

Distance between centers (A1-6. A2-6) 767,1067mm 767,1067,1667mm

Width of bed 300 mm

Stroke of tool post 145 mm

Stroke of cross slide 265 mm

Spindle bore 51 mm 58mm (78 mm opt.)

Taper of spindle bore & center MT6 x MT4

Spindle nose A1-6. D1-6(A2-6.02-6,D1-8 opt.)

Number of spindle speeds 8 or 16 12

70, 110,180,290,430, Ø58 mm:35,52.75,110,160,230,330,490,650,950,1350,2000 r.p.m.

Spindle speed (220V/60 Hz) 690,1125,1800 r.p.m. Ø78 mm:29,43,62,90,130,190,275,405,540,790,1120,1650 r.p.m.

16step:4P:65,125,210,320,370,695,120,1800 r.p.m / 8P:33,62,105,160,185,348,600,900 r.p.m

for FCH-1600

Number of feeds 36

Range of longitudinal feeds (metric) 0.07-0.50 mm/rev 0.037-1.04 mm/rev(P=6mm)

0.035-0.98 mm/rev (4 TPI)

Range of cross feeds 1/2 Half oflongitudinal feeds

Leadscrew diameter / pitch 35 mm / 4 TPI, P-6 mm

Range of inch pitches 4-42 TPI (36 kinds) 2~72 TPI (44 kinds)

Rango of metric pitches 0.4-7.0 mm (36 kinds) 0.2~14 mm (39 kinds)

Qu'll stroke / diameter / taper 170 mm / 60 mm / MT#4

Main motor (30 min.) 5 HP (7.5 HP opt.)

Coolant pump motor 1/8 HP

Floor space 2050,2345,2960 x 1040 x 1400 mm

Weight 1450,1550 kgs 1500,1600,1800 kgs 1600,1700,1900 kgs

STANDARD ACCEESSORIES : OPTIONAL ACCESSORIES :

● 9” 3-jaws chuck with back plate ● Follow rest ● Full length splash guard

● Leveling screws ● Face plate (350 mm) ● Drill attachment

● Service kits & tool box ● 4-position carriage stop ● Spindle bore 78mm with 10” 3-jaws chuck

● Main motor 5 HP /4 P ● Taper turning attachment &back plate( for FCH-1700/2100)

● Steady rest ● 3 jaws chuck ● Digital readout

● Coolant system ● 4 jaws independent chuck ● Center sleeve MT6×MT4

● Multi-position length stop ● Rear toolpost ● Dead center (MT4) 2 pcs

● Work light ● Main motor7.5 HP/4P ● Inverter for FCH-1600:70~1800rpm

136