Page 142 - metal2022

P. 142

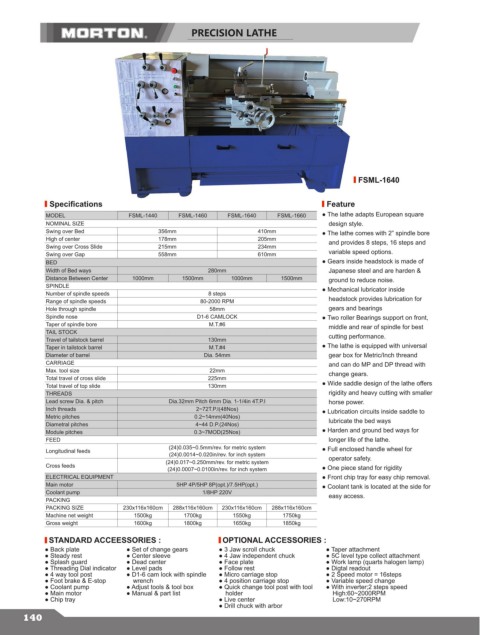

PRECISION LATHE

FSML-1640

Specifications Feature

MODEL FSML-1440 FSML-1460 FSML-1640 FSML-1660 ● The lathe adapts European square

NOMINAL SIZE design style.

Swing over Bed 356mm 410mm ● The lathe comes with 2” spindle bore

High of center 178mm 205mm and provides 8 steps, 16 steps and

Swing over Cross Slide 215mm 234mm

Swing over Gap 558mm 610mm variable speed options.

BED ● Gears inside headstock is made of

Width of Bed ways 280mm Japanese steel and are harden &

Distance Between Center 1000mm 1500mm 1000mm 1500mm ground to reduce noise.

SPINDLE ● Mechanical lubricator inside

Number of spindle speeds 8 steps

Range of spindle speeds 80-2000 RPM headstock provides lubrication for

Hole through spindle 58mm gears and bearings

Spindle nose D1-6 CAMLOCK ● Two roller Bearings support on front,

Taper of spindle bore M.T.#6 middle and rear of spindle for best

TAIL STOCK cutting performance.

Travel of tailstock barrel 130mm

Taper in tailstock barrel M.T.#4 ● The lathe is equipped with universal

Diameter of barrel Dia. 54mm gear box for Metric/Inch threand

CARRIAGE and can do MP and DP thread with

Max. tool size 22mm change gears.

Total travel of cross slide 225mm

Total travel of top slide 130mm ● Wide saddle design of the lathe offers

THREADS rigidity and heavy cutting with smaller

Lead screw Dia. & pitch Dia.32mm Pitch 6mm Dia. 1-1/4in 4T.P.I horse power.

Inch threads 2~72T.P.I(48Nos) ● Lubrication circuits inside saddle to

Metric pitches 0.2~14mm(40Nos) lubricate the bed ways

Diametral pitches 4~44 D.P.(24Nos)

Module pitches 0.3~7MOD(25Nos) ● Harden and ground bed ways for

FEED longer life of the lathe.

(24)0.035~0.5mm/rev. for metric system ● Full enclosed handle wheel for

Longitudinal feeds

(24)0.0014~0.020in/rev. for inch system operator safety.

(24)0.017~0.250mm/rev. for metric system

Cross feeds ● One piece stand for rigidity

(24)0.0007~0.0100in/rev. for inch system

ELECTRICAL EQUIPMENT ● Front chip tray for easy chip removal.

Main motor 5HP 4P/5HP 8P(opt.)/7.5HP(opt.) ● Coolant tank is located at the side for

Coolant pump 1/8HP 220V easy access.

PACKING

PACKING SIZE 230x116x160cm 288x116x160cm 230x116x160cm 288x116x160cm

Machine net weight 1500kg 1700kg 1550kg 1750kg

Gross weight 1600kg 1800kg 1650kg 1850kg

STANDARD ACCEESSORIES : OPTIONAL ACCESSORIES :

● Back plate ● Set of change gears ● 3 Jaw scroll chuck ● Taper attachment

● Steady rest ● Center sleeve ● 4 Jaw independent chuck ● 5C level type collect attachment

● Splash guard ● Dead center ● Face plate ● Work lamp (quarts halogen lamp)

● Threading Dial indicator ● Level pads ● Follow rest ● Digtal readout

● 4 way tool post ● D1-6 cam lock with spindle ● Micro carriage stop ● 2 Speed motor = 16steps

● Foot brake & E-stop wrench ● 4 position carriage stop ● Variable speed change

● Coolant pump ● Adjust tools & tool box ● Quick change tool post with tool ● With inverter;2 steps speed

● Main motor ● Manual & part list holder High:60~2000RPM

● Chip tray ● Live center Low:10~270RPM

● Drill chuck with arbor

140