Page 44 - metal2022

P. 44

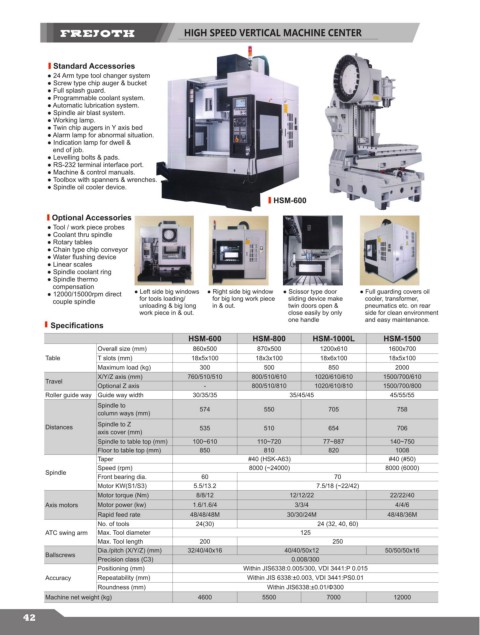

HIGH SPEED VERTICAL MACHINE CENTER

Standard Accessories

● 24 Arm type tool changer system

● Screw type chip auger & bucket

● Full splash guard.

● Programmable coolant system.

● Automatic lubrication system.

● Spindle air blast system.

● Working lamp.

● Twin chip augers in Y axis bed

● Alarm lamp for abnormal situation.

● Indication lamp for dwell &

end of job.

● Levelling bolts & pads.

● RS-232 terminal interface port.

● Machine & control manuals.

● Toolbox with spanners & wrenches.

● Spindle oil cooler device.

HSM-600

Optional Accessories

● Tool / work piece probes

● Coolant thru spindle

● Rotary tables

● Chain type chip conveyor

● Water flushing device

● Linear scales

● Spindle coolant ring

● Spindle thermo

compensation

● 12000/15000rpm direct ● Left side big windows ● Right side big window ● Scissor type door ● Full guarding covers oil

couple spindle for tools loading/ for big long work piece sliding device make cooler, transformer,

unloading & big long in & out. twin doors open & pneumatics etc. on rear

work piece in & out. close easily by only side for clean environment

one handle and easy maintenance.

Specifications

HSM-600 HSM-800 HSM-1000L HSM-1500

Overall size (mm) 860x500 870x500 1200x610 1600x700

Table T slots (mm) 18x5x100 18x3x100 18x6x100 18x5x100

Maximum load (kg) 300 500 850 2000

X/Y/Z axis (mm) 760/510/510 800/510/610 1020/610/610 1500/700/610

Travel

Optional Z axis - 800/510/810 1020/610/810 1500/700/800

Roller guide way Guide way width 30/35/35 35/45/45 45/55/55

Spindle to 574 550 705 758

column ways (mm)

Distances Spindle to Z 535 510 654 706

axis cover (mm)

Spindle to table top (mm) 100~610 110~720 77~887 140~750

Floor to table top (mm) 850 810 820 1008

Taper #40 (HSK-A63) #40 (#50)

Speed (rpm) 8000 (~24000) 8000 (6000)

Spindle

Front bearing dia. 60 70

Motor KW(S1/S3) 5.5/13.2 7.5/18 (~22/42)

Motor torque (Nm) 8/8/12 12/12/22 22/22/40

Axis motors Motor power (kw) 1.6/1.6/4 3/3/4 4/4/6

Rapid feed rate 48/48/48M 30/30/24M 48/48/36M

No. of tools 24(30) 24 (32, 40, 60)

ATC swing arm Max. Tool diameter 125

Max. Tool length 200 250

Dia./pitch (X/Y/Z) (mm) 32/40/40x16 40/40/50x12 50/50/50x16

Ballscrews

Precision class (C3) 0.008/300

Positioning (mm) Within JIS6338:0.005/300, VDI 3441:P 0.015

Accuracy Repeatability (mm) Within JIS 6338:±0.003, VDI 3441:PS0.01

Roundness (mm) Within JIS6338:±0.01/Φ300

Machine net weight (kg) 4600 5500 7000 12000

42