Page 61 - metal2022

P. 61

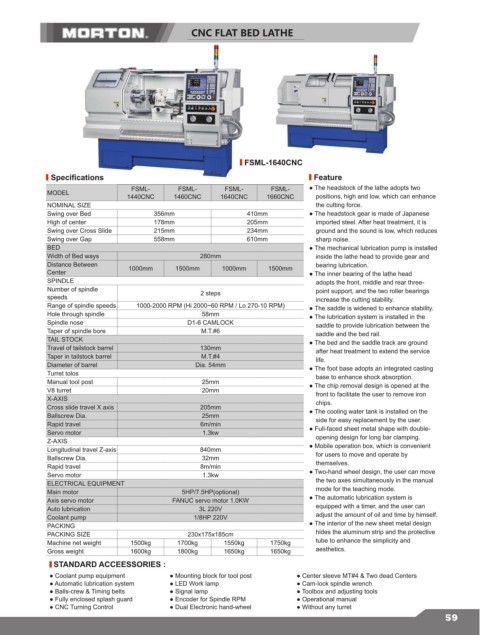

CNC FLAT BED LATHE

FSML-1640CNC

Specifications Feature

FSML- FSML- FSML- FSML- ● The headstock of the lathe adopts two

MODEL

1440CNC 1460CNC 1640CNC 1660CNC positions, high and low, which can enhance

NOMINAL SIZE the cutting force.

Swing over Bed 356mm 410mm ● The headstock gear is made of Japanese

High of center 178mm 205mm imported steel. After heat treatment, it is

Swing over Cross Slide 215mm 234mm ground and the sound is low, which reduces

Swing over Gap 558mm 610mm sharp noise.

BED ● The mechanical lubrication pump is installed

Width of Bed ways 280mm inside the lathe head to provide gear and

Distance Between 1000mm 1500mm 1000mm 1500mm bearing lubrication.

Center ● The inner bearing of the lathe head

SPINDLE adopts the front, middle and rear three-

Number of spindle 2 steps point support, and the two roller bearings

speeds increase the cutting stability.

Range of spindle speeds 1000-2000 RPM (Hi 2000~60 RPM / Lo 270-10 RPM) ● The saddle is widened to enhance stability.

Hole through spindle 58mm ● The lubrication system is installed in the

Spindle nose D1-6 CAMLOCK saddle to provide lubrication between the

Taper of spindle bore M.T.#6 saddle and the bed rail.

TAIL STOCK ● The bed and the saddle track are ground

Travel of tailstock barrel 130mm after heat treatment to extend the service

Taper in tailstock barrel M.T.#4 life.

Diameter of barrel Dia. 54mm ● The foot base adopts an integrated casting

Turret tolos base to enhance shock absorption.

Manual tool post 25mm ● The chip removal design is opened at the

V8 turret 20mm front to facilitate the user to remove iron

X-AXIS chips.

Cross slide travel X axis 205mm

Ballscrew Dia. 25mm ● The cooling water tank is installed on the

Rapid travel 6m/min side for easy replacement by the user.

Servo motor 1.3kw ● Full-faced sheet metal shape with double-

Z-AXIS opening design for long bar clamping.

Longitudinal travel Z-axis 840mm ● Mobile operation box, which is convenient

Ballscrew Dia. 32mm for users to move and operate by

Rapid travel 8m/min themselves.

Servo motor 1.3kw ● Two-hand wheel design, the user can move

ELECTRICAL EQUIPMENT the two axes simultaneously in the manual

Main motor 5HP/7.5HP(optional) mode for the teaching mode.

Axis servo motor FANUC servo motor 1.0KW ● The automatic lubrication system is

Auto lubrication 3L 220V equipped with a timer, and the user can

Coolant pump 1/8HP 220V adjust the amount of oil and time by himself.

PACKING ● The interior of the new sheet metal design

PACKING SIZE 230x175x185cm hides the aluminum strip and the protective

Machine net weight 1500kg 1700kg 1550kg 1750kg tube to enhance the simplicity and

Gross weight 1600kg 1800kg 1650kg 1650kg aesthetics.

STANDARD ACCEESSORIES :

● Coolant pump equipment ● Mounting block for tool post ● Center sleeve MT#4 & Two dead Centers

● Automatic lubrication system ● LED Work lamp ● Cam-lock spindle wrench

● Balls-crew & Timing belts ● Signal lamp ● Toolbox and adjusting tools

● Fully enclosed splash guard ● Encoder for Spindle RPM ● Operational manual

● CNC Turning Control ● Dual Electronic hand-wheel ● Without any turret

59