Page 278 - metal2022

P. 278

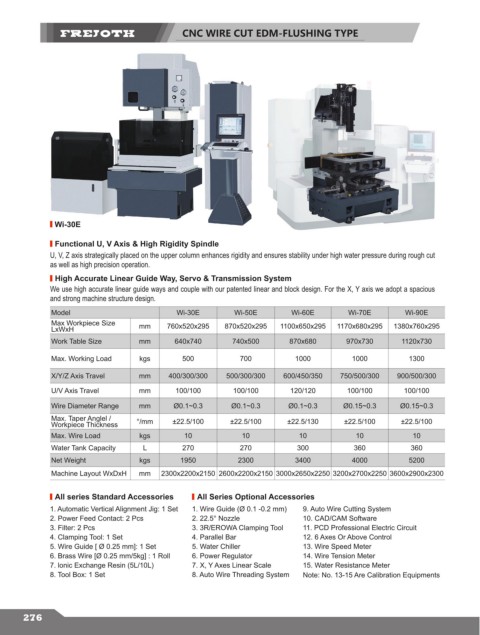

CNC WIRE CUT EDM-FLUSHING TYPE

Wi-30E

Functional U, V Axis & High Rigidity Spindle

U, V, Z axis strategically placed on the upper column enhances rigidity and ensures stability under high water pressure during rough cut

as well as high precision operation.

High Accurate Linear Guide Way, Servo & Transmission System

We use high accurate linear guide ways and couple with our patented linear and block design. For the X, Y axis we adopt a spacious

and strong machine structure design.

Model Wi-30E Wi-50E Wi-60E Wi-70E Wi-90E

Max Workpiece Size mm 760x520x295 870x520x295 1100x650x295 1170x680x295 1380x760x295

LxWxH

Work Table Size mm 640x740 740x500 870x680 970x730 1120x730

Max. Working Load kgs 500 700 1000 1000 1300

X/Y/Z Axis Travel mm 400/300/300 500/300/300 600/450/350 750/500/300 900/500/300

U/V Axis Travel mm 100/100 100/100 120/120 100/100 100/100

Wire Diameter Range mm Ø0.1~0.3 Ø0.1~0.3 Ø0.1~0.3 Ø0.15~0.3 Ø0.15~0.3

Max. Taper Anglel / °/mm ±22.5/100 ±22.5/100 ±22.5/130 ±22.5/100 ±22.5/100

Workpiece Thickness

Max. Wire Load kgs 10 10 10 10 10

Water Tank Capacity L 270 270 300 360 360

Net Weight kgs 1950 2300 3400 4000 5200

Machine Layout WxDxH mm 2300x2200x2150 2600x2200x2150 3000x2650x2250 3200x2700x2250 3600x2900x2300

All series Standard Accessories All Series Optional Accessories

1. Automatic Vertical Alignment Jig: 1 Set 1. Wire Guide (Ø 0.1 -0.2 mm) 9. Auto Wire Cutting System

2. Power Feed Contact: 2 Pcs 2. 22.5° Nozzle 10. CAD/CAM Software

3. Filter: 2 Pcs 3. 3R/EROWA Clamping Tool 11. PCD Professional Electric Circuit

4. Clamping Tool: 1 Set 4. Parallel Bar 12. 6 Axes Or Above Control

5. Wire Guide [ Ø 0.25 mm]: 1 Set 5. Water Chiller 13. Wire Speed Meter

6. Brass Wire [Ø 0.25 mm/5kg] : 1 Roll 6. Power Regulator 14. Wire Tension Meter

7. lonic Exchange Resin (5L/10L) 7. X, Y Axes Linear Scale 15. Water Resistance Meter

8. Tool Box: 1 Set 8. Auto Wire Threading System Note: No. 13-15 Are Calibration Equipments

276