Page 284 - metal2022

P. 284

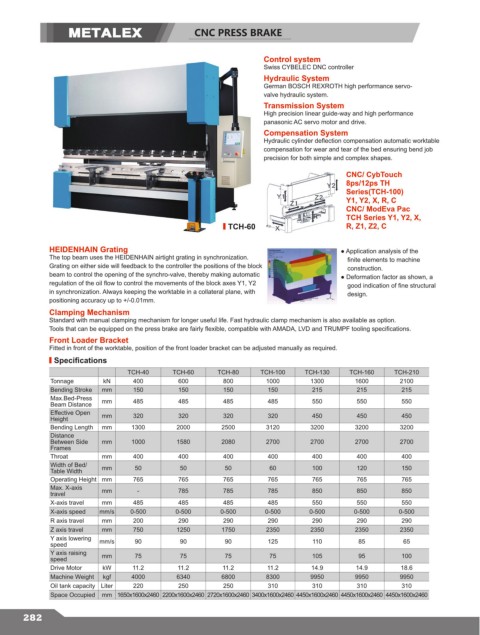

CNC PRESS BRAKE

Control system

Swiss CYBELEC DNC controller

Hydraulic System

German BOSCH REXROTH high performance servo-

valve hydraulic system.

Transmission System

High precision linear guide-way and high performance

panasonic AC servo motor and drive.

Compensation System

Hydraulic cylinder deflection compensation automatic worktable

compensation for wear and tear of the bed ensuring bend job

precision for both simple and complex shapes.

CNC/ CybTouch

8ps/12ps TH

Series(TCH-100)

Y1, Y2, X, R, C

CNC/ ModEva Pac

TCH Series Y1, Y2, X,

TCH-60 R, Z1, Z2, C

HEIDENHAIN Grating ● Application analysis of the

The top beam uses the HEIDENHAIN airtight grating in synchronization. finite elements to machine

Grating on either side will feedback to the controller the positions of the block construction.

beam to control the opening of the synchro-valve, thereby making automatic ● Deformation factor as shown, a

regulation of the oil flow to control the movements of the block axes Y1, Y2 good indication of fine structural

in synchronization. Always keeping the worktable in a collateral plane, with design.

positioning accuracy up to +/-0.01mm.

Clamping Mechanism

Standard with manual clamping mechanism for longer useful life. Fast hydraulic clamp mechanism is also available as option.

Tools that can be equipped on the press brake are fairly flexible, compatible with AMADA, LVD and TRUMPF tooling specifications.

Front Loader Bracket

Fitted in front of the worktable, position of the front loader bracket can be adjusted manually as required.

Specifications

TCH-40 TCH-60 TCH-80 TCH-100 TCH-130 TCH-160 TCH-210

Tonnage kN 400 600 800 1000 1300 1600 2100

Bending Stroke mm 150 150 150 150 215 215 215

Max.Bed-Press mm 485 485 485 485 550 550 550

Beam Distance

Effective Open mm 320 320 320 320 450 450 450

Height

Bending Length mm 1300 2000 2500 3120 3200 3200 3200

Distance

Between Side mm 1000 1580 2080 2700 2700 2700 2700

Frames

Throat mm 400 400 400 400 400 400 400

Width of Bed/ mm 50 50 50 60 100 120 150

Table Width

Operating Height mm 765 765 765 765 765 765 765

Max. X-axis mm - 785 785 785 850 850 850

travel

X-axis travel mm 485 485 485 485 550 550 550

X-axis speed mm/s 0-500 0-500 0-500 0-500 0-500 0-500 0-500

R axis travel mm 200 290 290 290 290 290 290

Z axis travel mm 750 1250 1750 2350 2350 2350 2350

Y axis lowering mm/s 90 90 90 125 110 85 65

speed

Y axis raising mm 75 75 75 75 105 95 100

speed

Drive Motor kW 11.2 11.2 11.2 11.2 14.9 14.9 18.6

Machine Weight kgf 4000 6340 6800 8300 9950 9950 9950

Oil tank capacity Liter 220 250 250 310 310 310 310

Space Occupied mm 1650x1600x2460 2200x1600x2460 2720x1600x2460 3400x1600x2460 4450x1600x2460 4450x1600x2460 4450x1600x2460

282