Page 51 - metal2022

P. 51

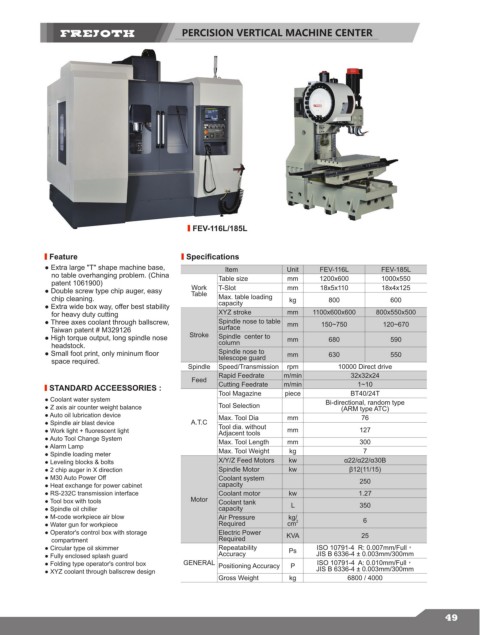

PERCISION VERTICAL MACHINE CENTER

FEV-116L/185L

Feature Specifications

● Extra large "T" shape machine base, Item Unit FEV-116L FEV-185L

no table overhanging problem. (China Table size mm 1200x600 1000x550

patent 1061900)

● Double screw type chip auger, easy Work T-Slot mm 18x5x110 18x4x125

Table

chip cleaning. Max. table loading kg 800 600

● Extra wide box way, offer best stability capacity

for heavy duty cutting XYZ stroke mm 1100x600x600 800x550x500

● Three axes coolant through ballscrew, Spindle nose to table mm 150~750 120~670

Taiwan patent # M329126 surface

● High torque output, long spindle nose Stroke Spindle center to mm 680 590

headstock. column

● Small foot print, only mininum floor Spindle nose to mm 630 550

space required. telescope guard

Spindle Speed/Transmission rpm 10000 Direct drive

Rapid Feedrate m/min 32x32x24

Feed

1~10

STANDARD ACCEESSORIES : Cutting Feedrate m/min BT40/24T

Tool Magazine

piece

● Coolant water system Bi-directional, random type

● Z axis air counter weight balance Tool Selection (ARM type ATC)

● Auto oil lubrication device Max. Tool Dia mm 76

● Spindle air blast device A.T.C Tool dia. without

● Work light + fluorescent light Adjacent tools mm 127

● Auto Tool Change System Max. Tool Length mm 300

● Alarm Lamp

● Spindle loading meter Max. Tool Weight kg 7

● Leveling blocks & bolts X/Y/Z Feed Motors kw α22/α22/α30B

● 2 chip auger in X direction Spindle Motor kw β12(11/15)

● M30 Auto Power Off Coolant system 250

● Heat exchange for power cabinet capacity

● RS-232C transmission interface Coolant motor kw 1.27

● Tool box with tools Motor Coolant tank L 350

● Spindle oil chiller capacity

● M-code workpiece air blow Air Pressure kg/ 6

● Water gun for workpiece Required cm 2

● Operator's control box with storage Electric Power KVA 25

compartment Required

● Circular type oil skimmer Repeatability Ps ISO 10791-4 R: 0.007mm/Full,

● Fully enclosed splash guard Accuracy JIS B 6336-4 ± 0.003mm/300mm

● Folding type operator's control box GENERAL Positioning Accuracy P ISO 10791-4 A: 0.010mm/Full,

● XYZ coolant through ballscrew design JIS B 6336-4 ± 0.003mm/300mm

Gross Weight kg 6800 / 4000

49